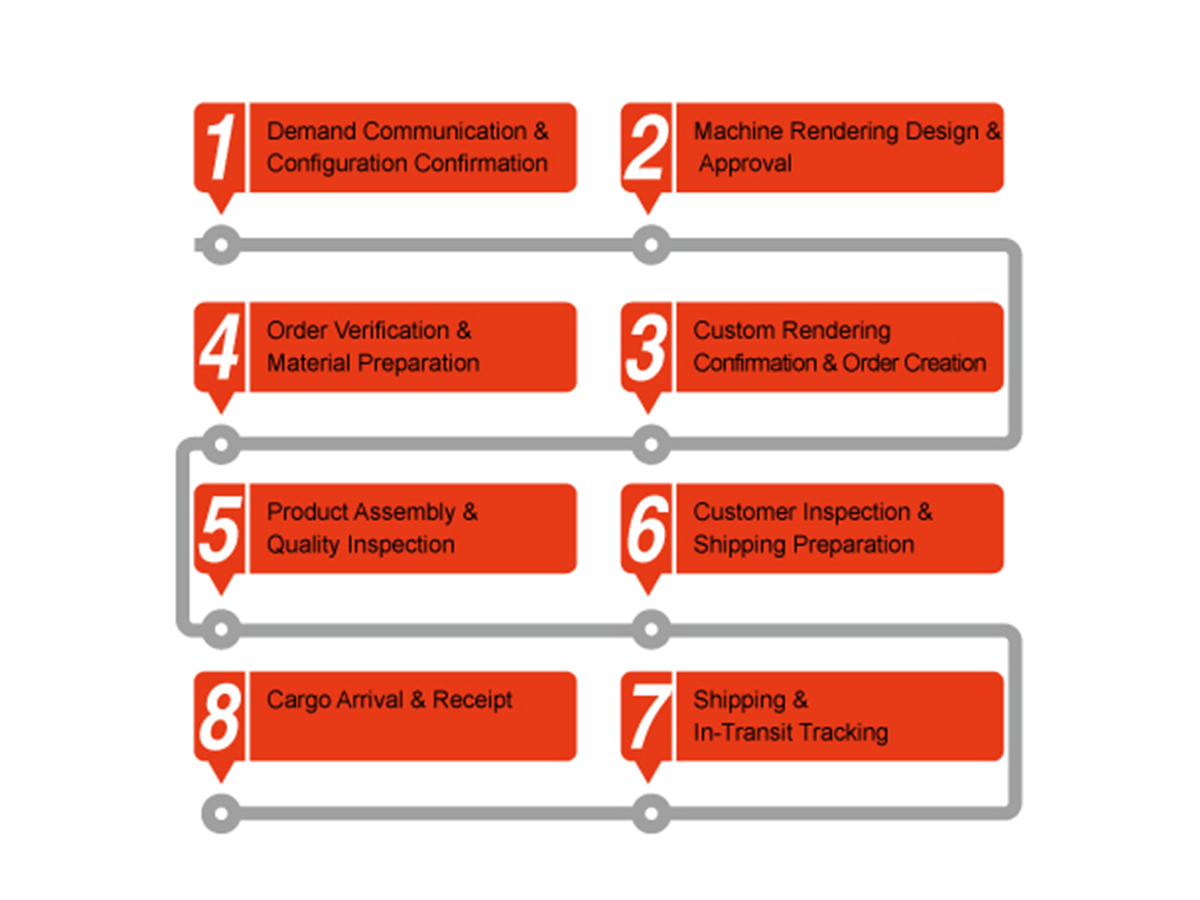

1. Demande de communication et confirmation de la configuration du modèle

Recueil des demandes des clients :

Entretenez une communication approfondie avec les clients pour clarifier leurs besoins personnalisés, y compris les modèles de machines (par exemple, XS60), les préférences de couleur et les exigences de configuration de base.

Confirmez si les modèles fournis par les clients sont compatibles avec la gamme de produits existante de l'entreprise ou nécessitent une personnalisation particulière.

Formulation du plan de personnalisation :

Développez un plan de personnalisation détaillé en fonction des besoins du client, y compris des détails spécifiques tels que les modèles de machines, les couleurs et les configurations.

Mettre l’accent sur les droits exclusifs de l’agence en tant que client ODM pour garantir l’exclusivité du marché pour leurs réalisations innovantes.

2. Conception et confirmation du rendu de la machine

Soumission de l'identité de la marque et des spécifications :

Les clients soumettent des logos de marque, des spécifications de conception et des exigences particulières.

Conception de rendu :

Le département de conception de l'entreprise conçoit le rendu de l'apparence de la machine en fonction des besoins du client et des spécifications de la marque, y compris les couleurs, les effets d'autocollant de logo, etc.

Fournir des ébauches de conception préliminaires pour examen par le client et itérer les optimisations en fonction des commentaires.

3. Confirmation de rendu personnalisé et génération de commande

Confirmation de rendu :

Les ventes et les clients confirment conjointement le rendu personnalisé final pour garantir qu'il répond aux besoins des clients.

Génération de commandes :

Générez un ordre de coopération formel basé sur le rendu confirmé, en clarifiant les termes clés tels que les spécifications du produit, la quantité, le prix et la date de livraison.

4. Confirmation de commande et préparation du matériel

Confirmation de commande :

Une fois que le client a confirmé la commande, l'entreprise commence à organiser la production de la machine.

Conception et production de matériaux personnalisés :

Le département de conception conçoit une série de matériaux personnalisés en fonction des exigences de la commande, notamment des autocollants, des plaques signalétiques, des manuels, des emballages, etc.

Livrer les matériaux conçus aux fournisseurs pour la production afin d'assurer la synchronisation avec les calendriers de production des machines.

5. Assemblage du produit et contrôle qualité

Assemblage du produit :

Assembler des produits personnalisés selon les exigences du client.

Contrôle qualité de l'entreprise :

Effectuer une inspection qualité complète au niveau de l'entreprise des produits personnalisés pour garantir que la qualité des produits répond aux attentes des clients.

6. Contrôle qualité client et préparation de l'expédition

Contrôle qualité client :

Invitez le personnel spécifié par le client à l’usine pour l’inspection de la qualité du produit ou fournissez des solutions d’inspection de qualité à distance.

Après avoir passé l'inspection qualité, emballez les produits selon les exigences du client et préparez-les pour le chargement et l'expédition.

7. Suivi des expéditions et des transits

Chargement et expédition :

Chargez les produits selon le temps convenu et les clients peuvent effectuer une supervision sur place ou une surveillance à distance.

Suivi en transit :

L'équipe de vente suit l'état de l'expédition et informe régulièrement les clients de la dynamique du fret pour s'assurer qu'ils comprennent l'heure d'arrivée estimée.

8. Arrivée et réception de la cargaison au port

Arrivée de la cargaison au port :

Informez rapidement les clients après l’arrivée de la cargaison au port de destination.

Reçu client :

Les clients signent pour les marchandises et confirment la fin du processus de commande.

Fournir un service après-vente continu pour assurer la satisfaction du client.